201 304 316 Grade Decorative Panel PVD Color Coating Stainless Steel Sheet and Plate

|

Product Name

|

High Quality PVD Color Coating Etched Design Plate Stainless Steel Sheet/Plate

|

|

Material

|

201,301,304,304L,316,316L,410,430,etc

|

|

Thickness

|

0.15 to 80mm

|

|

Width

|

100-1525mm

|

|

Length

|

500-6000mm

|

|

Surface

|

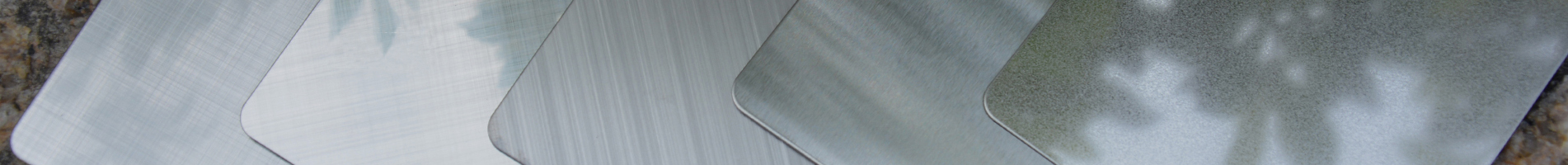

No.4,Hairline(brushed),8k mirror, Etching,Embossed,Vibration, No 4 brushed, Sand blasting, PVD coating,etc.

|

|

Color

|

Champagne, rose gold, rose red, coffee gold, black gold, brown, black, red copper, antique copper, brass, titanium, grey, violet,bronze, sapphire, jade green, etc.

|

|

Pattern

|

Water ripple,linen,cubes,diamond,panda,bamboo, vibration etc.

|

|

MOQ

|

30 pieces

|

|

Application

|

Hotel Decoration, Construction, Elevator, Electric Appliance, Door,etc.

|

|

Delivery

|

5-20 days

|

|

Standard Specification

|

1000*2000mm, 1219*2438mm, 1219*3048mm, customized

|

Available Colors:black titanium, titanium, titanium white, sky blue, sapphire blue, coffee, tea, purple, bronze, bronze, champagne gold, rose gold, purple, emerald green, green, etc.

-

Water Ripple Stamped Stainless Steel Sheet

The production process of PVD color coating on stainless steel sheets involves the following steps:

1. Surface Preparation: The stainless steel sheets undergo thorough cleaning and surface preparation to ensure the removal of any dirt, grease, or contaminants. This step is crucial for achieving good adhesion between the PVD coating and the stainless steel surface.

2. Loading: The prepared stainless steel sheets are loaded into a vacuum chamber, which is a controlled environment for the PVD process.

3. Pumping Down: The chamber is evacuated to create a vacuum environment by removing air and other gases. This is important to ensure the purity of the deposition process and prevent contamination.

4. Preheating (Optional): In some cases, the stainless steel sheets may be preheated to a specific temperature. Preheating can enhance the adhesion of the PVD coating to the stainless steel surface.

5. Metal Deposition: The PVD process involves the deposition of metal atoms or ions onto the stainless steel sheets. This is typically achieved through one of the following methods:

a. Physical Vapor Deposition: A solid metal target, typically titanium, zirconium, or chromium, is bombarded with high-energy ions in a process known as sputtering. The metal atoms are then vaporized and deposited onto the stainless steel surface.

b. Cathodic Arc Deposition: A high voltage is applied to a metal cathode, causing a metal vapor to be generated through an electric arc. This vapor is then directed toward the stainless steel sheets.

6. Color Coating: During the metal deposition process, reactive gases such as nitrogen or a mixture of nitrogen and acetylene may be introduced into the chamber. These gases react with the metal atoms, forming metal nitrides or carbides, which create the desired color effect on the stainless steel sheets. The composition and ratio of gases can be adjusted to achieve specific colors and finishes.

7. Cooling and Venting: After the deposition and color coating, the stainless steel sheets are cooled to room temperature. The chamber is then vented to reintroduce air and restore atmospheric pressure.

8. Inspection and Quality Control: The coated stainless steel sheets undergo visual inspection and quality control measures to ensure uniformity, adhesion, color accuracy, and overall product quality.

9. Further Processing: The coated stainless steel sheets can undergo additional processes such as cutting, shaping, forming, and surface treatments as required for specific applications.

The exact details of the production process may vary depending on the equipment used and the manufacturer's specific requirements.

Application of PVD color coating on stainless steel sheets

FAQ:

Q1:What are HERMES's products?

A1:HERMES's main products include 200/300/400series stainless steel coils/ sheets/tiling trims/strips/circles with all different styles of etched, embossed, mirror polishing, brushed, and PVD color coating, etc.

Q2:How can you ensure the quality of your product?

A2:All products have to go through three checks in the whole manufacturing process, which include production, cutting, and packing.

Q3:What is your delivery time and supply ability?

The delivery time is normally within 15~20 working days and we can supply about 15,000 tons every month.

Q4:About the complaint, quality problem, after-sales service, etc, how do you handle it?

A4:We will have certain colleagues follow our orders accordingly. Each order is equipped with professional after-sales service. If any claim happened, we will take responsibility and compensate you as per the contract. To better serve our clients, we'll keep track of feedback on our products from clients and that's what makes us different from other suppliers. We're a customer care enterprise.

Q5:What is the MOQ?

A5:We don't have MOQ. We treat every order with heart. If you are scheduling to place a trial order, pls feel free to contact us and we can meet your requirements.

Q6:Can you provide OEM or ODM service?

A6:Yes, we have a strong developing team. The products can be made according to your request.

Q7:How to clean and maintain its surface?

A7:Use neutral cleanser and soft cotton cloth. Do not use acid cleanser and rough material.

REQUEST A QUOTATION

If you are interested in our products and would like to know more details, please leave a message here, and we will reply to you as soon as we can.

Foshan Hermes Steel Co., Limited, establishes a large stainless steel comprehensive service platform integrating international trading, processing, storage and after-sales service.

Our company is located in Foshan Liyuan Metal Trading Center, which is a large stainless steel distribution and trading area in southern China, with convenient transportation and mature industrial supporting facilities. A lot of merchants gathered around the market center. Combining the advantages of market location with strong technologies and scales of major steel mills, Hermes Steel takes full advantages in the field of distribution and quickly shares market information. After more than 10 years of unremitting operation, Hermes Steel establishes professional teams of international trading, large warehousing, processing and after-sales service, providing professional stainless steel import and export trading services to our international customers with fast response, stable supreme quality, strong after-sales support and excellent reputation.

Hermes Steel has a wide range of products and services, covering stainless steel coils, stainless steel sheets, stainless steel pipes, stainless steel bars, stainless steel wires and customized stainless steel products, with steel grades 200 series, 300 series, 400 series; including surface finish like NO.1, 2E, 2B, 2BB, BA, NO.4, 6K, 8K. In addition to meet the individual needs of our customers, we also provide customized 2BQ (stamping material), 2BK (8K processing special material) and other special material, with customized surface’s processing including mirror, grinding, sandblasting, etching, embossing, stamping, lamination, 3D laser, antique, Anti-fingerprint, PVD vacuum coating and water plating. At the same time, we provide with flattening, slitting, film covering, packaging and full sets of import or export trading services.

Foshan Hermes Steel Co., Limited. with years of experience in the field of stainless steel distribution, has been adhering to the aims of customer focus and service orientation, continuously building a professional sales and service team, providing professional solutions to satisfy customers’ various demands through prompt response and ultimately obtaining customer satisfaction to reflect the value of our enterprise. Our mission is to be a stainless steel company providing one-stop service to promptly satisfy the customers’ requirements.

In the process of providing customers with quality products and services for many years, we have gradually established our own corporate culture. Believing, sharing, altruism and persisstence are the pursuits of every staff from Hermes Steel.