PVD COLOR COATING STAINLESS STEEL SHEET

WHAT IS PVD TECHNOLOGY ?

PVD, Physical Vapor Deposition, is a process to produce a metal vapor that can be deposited on electrically conductive materials as a thin highly adhered pure metal or alloy coating.

Product Advantage

Hermes Steel is equipped with high temperature vacuum furnace, adopting the world first-class PVD technology, which makes the color coating strongly attached to stainless steel surface, color is even and stable.

All colors can be combined with Mirror finish, Hairline finish, Embossed finish, Vibration finish and Etching finish, etc.

Product Information

|

Surface |

Vibration Finish |

|||

|

Grade |

201 |

304 |

316 |

430 |

|

Form |

Sheet only |

|||

|

Material |

Prime and suitable for surface processing |

|||

|

Thickness |

0.3-3.0 mm |

|||

|

Width |

1000/1219/1250/1500 mm & customized |

|||

|

Length |

Max 4000mm & customized |

|||

|

Available Colors |

Gold, champagne, nickel silver, black, bronze, copper, blue, green, coffee, violet, etc |

|||

|

Remarks |

Your specific color sample can be provided for matching. Special dimensions are accepted on request. Customized specific cut-to-length, laser-cut, bending are acceptable. |

|||

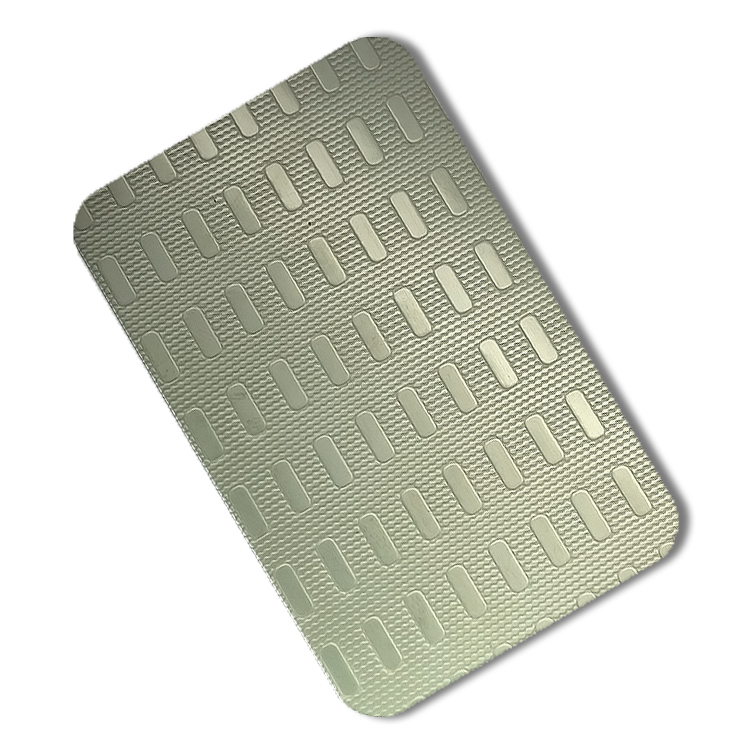

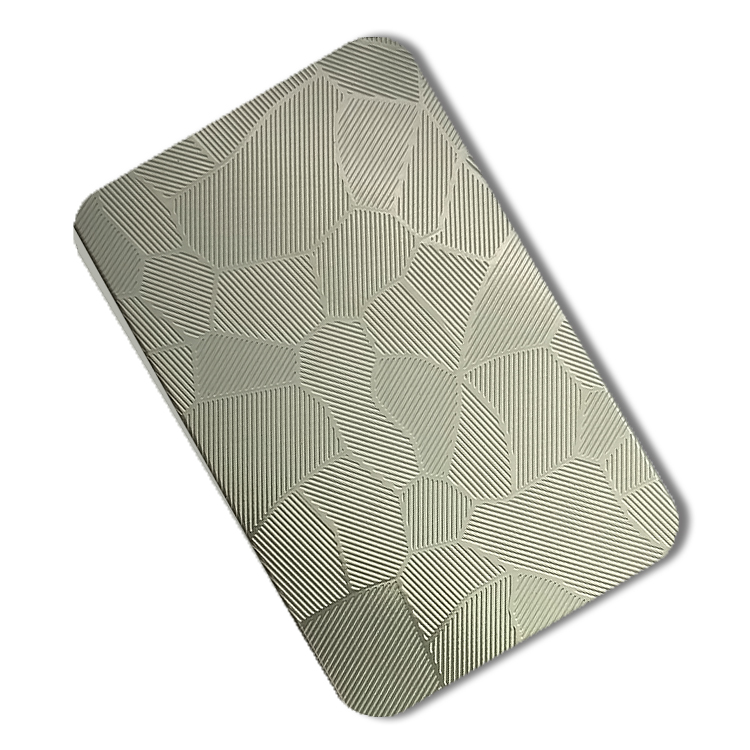

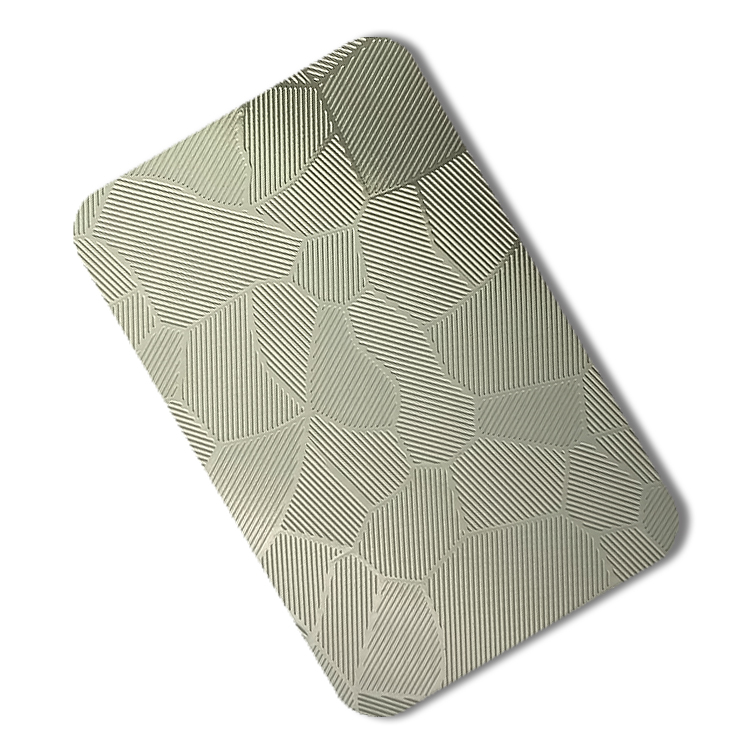

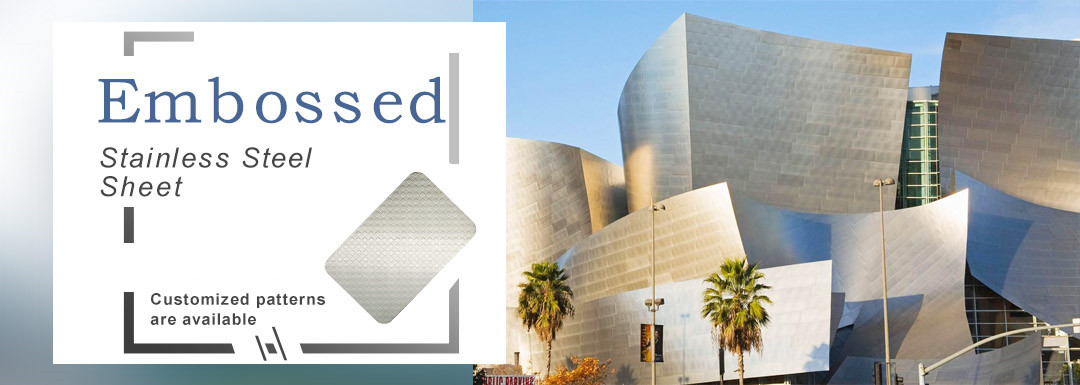

Various Pattern For Your Choose

Customized patterns are available here or you can choose our existing patterns

If you want to know more about the patterns of PVD Color Coating stainless steel sheet, please download our product catalogue

Product Application

PVD Color Coating stainless steel sheets are widely used in architectural and decorative applications, such as hotel and restaurant decoration, wall panel, coping and trim, advertising board, also artistic objects.

Product Packing Ways

|

Protective Film |

1. Double layer or single layer. 2. Black and white PE film/Laser (POLI) film. |

|

Packing Details |

1. Wrap with waterproof paper. 2. Cardboard encase all packs of the sheet. 3. The strap aligned with edge protection. |

|

Packing Case |

Strong wooden case, metal pallet and customized pallet are acceptable. |