-

Manufacturing principle and etching process of color stainless steel etch plate

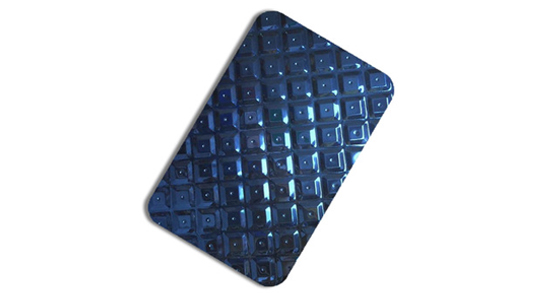

Stainless steel etching pattern process plate is on the surface of stainless steel through chemical methods, corrosion out of a variety of patterns. 8K mirror plate, electroplate, antique copper plate as the bottom plate, etch treatment, the surface of the object for further processing. Color st...Read more -

Stainless steel daily tips: stainless steel laminating plate remove the film method

There are two ways to completely clean the stainless steel laminate film: The first kind is electric hot wind heating pull side tear. The second kind, is to dip in ethyl acetate with a cloth (specially dissolved protective film glue chemical solvent) bubble, but pay attention to tear the protect...Read more -

Daily maintenance of color stainless steel

1, surface dust and dirt with soap weak lotion and warm water wash. 2, trademark, film with warm water and weak detergent to wash. The binder composition is scrubbed with alcohol or organic solvent. 3, the surface grease, oil, lubricating oil pollution, wipe with a soft cloth, colored stainless ...Read more -

The advantages of colorful stainless steel doors

1, safety and environmental protection: color stainless steel is an environmental protection decoration material, does not contain organic matter such as a, no shot, safety fire prevention. home 2, strong corrosion resistance: because the color does not cast steel plate not only maintain the phy...Read more -

Color stainless steel plate how to choose and buy

Stainless steel plate should have good corrosion resistance above all, we should consider the application of stainless steel plate, according to specific needs to judge whether the detailed specifications of rust. Stainless steel plate corrosion resistance is relative, often said stainless stee...Read more -

Advantages and application of color stainless steel plate

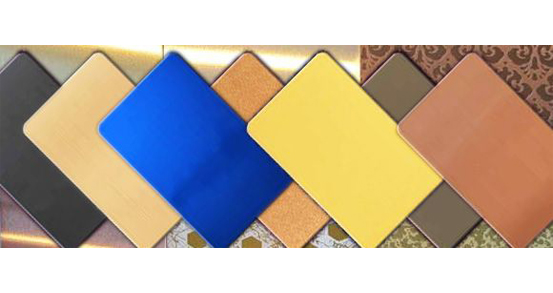

One: stainless steel is a kind of environmental protection decoration material, does not contain methanol and other organic matter, no radiation, safety fire prevention Two: on the basis of stainless steel, now there are color stainless steel, stainless steel etching technology, stainless steel ...Read more -

Color stainless steel coloring process classification

A. electroplating diandu Galvanization: the process of attaching a metal plate to the surface of a piece of metal or other material by electrolysis. It can prevent corrosion, improve wear resistance, electrical conductivity, reflection and improve aesthetics. B, water plating The process of form...Read more -

What are the features of stainless steel sheet stamping?

(1) high yield point, high hardness, significant cold hardening effect, easy to appear cracks and other defects. (2) poor thermal conductivity than ordinary carbon steel, resulting in the required deformation force, punching force, drawing force. (3) during drawing, the plastic deformation is se...Read more -

The advantages of color stainless steel fingerless plate

1, color stainless steel plate surface can adopt a new technology called no fingerprint processing technology, this technology is mainly using nanometer technology layer on the surface of stainless steel sheet color protective layer to form a very thin and very strong, because you can avoid peop...Read more -

Advantages of colored stainless steel laminate

Covered film is a physical process, a layer of film a layer of metal plate after high temperature and high pressure pressure. The advantages of laminating plate are: 1. Anti-lampblack: made of PVC high-gloss film, easy to clean. 2, wear resistance: special PET layer, durable. 3. Moisture-...Read more -

Color stainless steel features

1, color stainless steel plate surface can adopt a new technology called no fingerprint processing technology, this technology is mainly using nanometer technology layer on the surface of stainless steel sheet color protective layer to form a very thin and very strong, because you can avo...Read more -

Color stainless steel plate processing points

Color stainless steel plate because of its unique surface with a strong metallic texture of brilliant color and excellent corrosion resistance and widely used in high-end hotels, KTV and other decorative projects. At the same time, with the rapid development of stainless steel industry, color st...Read more -

Colorful stainless steel plate for a wide range of USES

Color stainless steel plate is a kind of environmental protection decoration material, no methanol and other organic matter, no radiation, fire safety, suitable for large construction decoration (bus station, railway station, subway station, airport, etc.), hotel and building business decoration...Read more -

Seven steps to remove color stainless steel door dirt

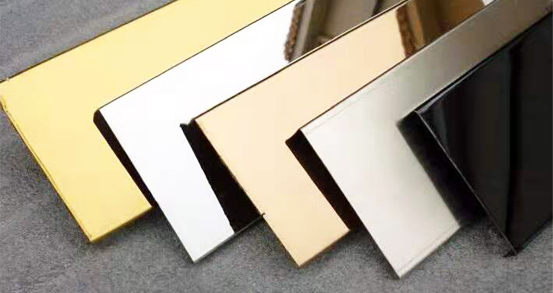

Color color stainless steel door here refers to a vacuum plating equipment of color or the water chemistry plating to get the color of the surface layer of color film, such as vacuum plating rose gold, black titanium, titanium gold, bronze, champagne, red wine, coffee, etc., water plating often ...Read more -

Color finished stainless steel solder joint treatment method

1. The paint The most direct way is to use the corresponding color repair paint to point, point to pay attention to the spray paint spray on the bottle cap, with a brush point, point in the welding spot, gently on the line, the area of the point should not be too large, in order to prevent broke...Read more -

Stainless steel color plate process classification

A. electroplating diandu Electroplating: the process of attaching a metal film to the surface of a piece of metal or other material by electrolysis. It can prevent corrosion, improve wear resistance, electrical conductivity, reflection and improve aesthetics. B, water plating The process of form...Read more