The stainless steel mirror effect refers to the highly reflective, mirror-like finish achieved on the surface of stainless steel sheets. This effect is the result of a specialized polishing and buffing process that creates a smooth, shiny surface with a high degree of reflectivity.

Process to Achieve the Mirror Effect

Material Selection:

High-quality stainless steel grades such as 304, 316, or 430 are typically used.

These grades are chosen for their excellent corrosion resistance, durability, and ability to be polished to a high sheen.

Polishing:

The stainless steel surface undergoes a series of grinding and polishing steps using increasingly finer abrasives.

This process removes imperfections, scratches, and surface irregularities, resulting in a smooth, uniform surface.

Buffing:

After polishing, the stainless steel is buffed using soft materials and compounds to enhance the shine and achieve a reflective finish.

Buffing further smoothens the surface and increases its gloss, creating the mirror-like appearance.

Characteristics of the Mirror Effect

Reflectivity:

The mirror effect results in a surface that can reflect images and light almost like a glass mirror.

This high reflectivity is due to the smoothness and evenness of the surface achieved through meticulous polishing.

Aesthetic Appeal:

The mirror-like finish is visually striking and adds a touch of elegance and sophistication to various applications.

It is often used in decorative and architectural elements to create a modern and high-end look.

Surface Smoothness:

The surface of mirror-finished stainless steel is extremely smooth, with very low roughness.

This smoothness not only contributes to the reflective quality but also makes the surface easier to clean and maintain.

The chemical composition of stainless steel varies depending on the specific grade and its intended application. Here are the details of the chemical composition for common grades of stainless steel:

304 Stainless Steel

304 Stainless Steel is the most commonly used austenitic stainless steel, known for its excellent corrosion resistance and formability. Its chemical composition typically includes:

- Carbon (C): ≤ 0.08%

- Manganese (Mn): ≤ 2.00%

- Silicon (Si): ≤ 0.75%

- Chromium (Cr): 18.00% – 20.00%

- Nickel (Ni): 8.00% – 10.50%

- Phosphorus (P): ≤ 0.045%

- Sulfur (S): ≤ 0.030%

316 Stainless Steel

316 Stainless Steel contains molybdenum, which enhances its resistance to chloride corrosion, making it suitable for marine environments and chemical processing equipment. Its chemical composition typically includes:

- Carbon (C): ≤ 0.08%

- Manganese (Mn): ≤ 2.00%

- Silicon (Si): ≤ 0.75%

- Chromium (Cr): 16.00% – 18.00%

- Nickel (Ni): 10.00% – 14.00%

- Molybdenum (Mo): 2.00% – 3.00%

- Phosphorus (P): ≤ 0.045%

- Sulfur (S): ≤ 0.030%

430 Stainless Steel

430 Stainless Steel is a ferritic stainless steel known for its good corrosion resistance and formability but lacks the high-temperature performance and corrosion resistance of 304 and 316. Its chemical composition typically includes:

- Carbon (C): ≤ 0.12%

- Manganese (Mn): ≤ 1.00%

- Silicon (Si): ≤ 1.00%

- Chromium (Cr): 16.00% – 18.00%

- Nickel (Ni): ≤ 0.75%

- Phosphorus (P): ≤ 0.040%

- Sulfur (S): ≤ 0.030%

201 Stainless Steel

201 Stainless Steel is an economical austenitic stainless steel with higher manganese and nitrogen content to partially replace nickel, commonly used in mild corrosive environments. Its chemical composition typically includes:

- Carbon (C): ≤ 0.15%

- Manganese (Mn): 5.50% – 7.50%

- Silicon (Si): ≤ 1.00%

- Chromium (Cr): 16.00% – 18.00%

- Nickel (Ni): 3.50% – 5.50%

- Phosphorus (P): ≤ 0.060%

- Sulfur (S): ≤ 0.030%

- Nitrogen (N): ≤ 0.25%

410 Stainless Steel

410 Stainless Steel is a martensitic stainless steel with high strength and hardness but lower corrosion resistance, commonly used in applications requiring high strength. Its chemical composition typically includes:

- Carbon (C): ≤ 0.15%

- Manganese (Mn): ≤ 1.00%

- Silicon (Si): ≤ 1.00%

- Chromium (Cr): 11.50% – 13.50%

- Nickel (Ni): ≤ 0.75%

- Phosphorus (P): ≤ 0.040%

- Sulfur (S): ≤ 0.030%

These chemical compositions determine the performance characteristics of each stainless steel grade, such as corrosion resistance, strength, hardness, and machinability. Depending on specific application requirements, the appropriate stainless steel grade can be selected to achieve optimal performance.

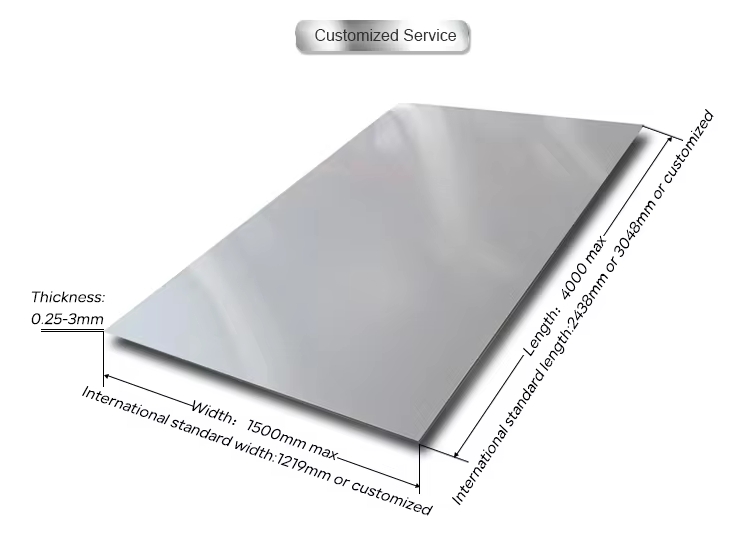

Standard Sizes:

Mirror stainless steel sheets are typically available in standard sizes, such as:

-

Thickness: Common thicknesses range from 0.25mm to 3mm, depending on the application requirements.

-

Width: Standard widths can vary from 1000mm to 1500mm or more, depending on the supplier and manufacturing process.

-

Length: Standard lengths often range from 2000mm to 4000mm or longer, but custom lengths may also be available.

Customization:

If standard sizes do not meet your requirements, custom-sized mirror stainless steel sheets can be fabricated to suit your specific needs. This allows for greater flexibility in design and ensures that the sheet size aligns precisely with your project requirements.

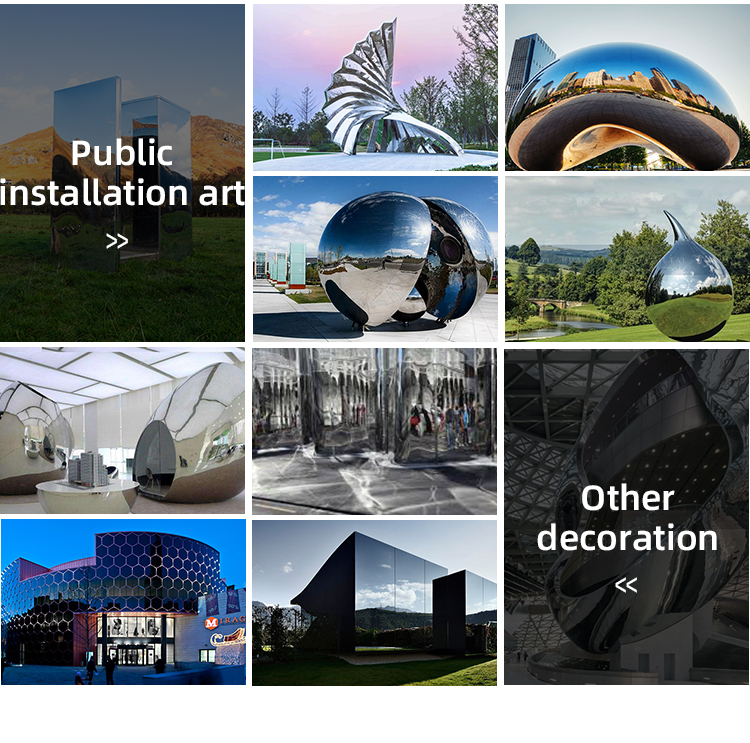

Applications of Stainless Steel with Mirror Effect

Architecture:

Used in building facades, interior cladding, and decorative panels.

Provides a sleek, modern aesthetic and can enhance the visual impact of structures.

Interior Design:

Commonly used for kitchen backsplashes, countertops, and wall panels.

Adds a luxurious feel to residential and commercial interiors.

Automotive:

Applied in trim, grilles, and other decorative components of vehicles to enhance appearance.

Signage and Displays:

Utilized in high-end signage, display panels, and advertising boards for its eye-catching effect.

Commercial and Industrial:

Used in environments requiring high levels of hygiene, such as food processing plants and hospitals, due to its easy-to-clean nature.

Q1:What is a mirror stainless steel sheet?

A1:A mirror stainless steel sheet refers to a stainless steel sheet that has undergone a specialized polishing process to achieve a highly reflective, mirror-like finish on its surface.

Q2:How is a mirror finish achieved on stainless steel?

A2:A mirror finish on stainless steel is achieved through a series of polishing and buffing processes using progressively finer abrasives until a smooth, reflective surface is obtained.

Q3:What are the applications of mirror stainless steel sheets?

A3:Mirror stainless steel sheets are commonly used in architectural and interior design projects for building facades, interior walls, decorative panels, kitchen backsplashes, countertops, automotive trim, signage, and displays.

Q4:What are the benefits of using mirror stainless steel sheets?

A4:The benefits include a sleek, modern aesthetic, high reflectivity, durability, corrosion resistance, ease of maintenance, and suitability for various indoor and outdoor applications.

Q5:What grades of stainless steel are used for mirror finishes?

A5:Common grades include 304, 316, and 430 stainless steel. Grade 316 is preferred for applications requiring enhanced corrosion resistance, such as marine environments.

Q6:How do you clean and maintain mirror stainless steel sheets?

A6:Mirror stainless steel sheets can be cleaned using mild detergent solutions and soft cloths or sponges. Avoid abrasive cleaners or scrubbing pads that could scratch the surface. Regular cleaning helps maintain the reflective quality.

Q7:Can mirror stainless steel sheets be customized?

A7:Yes, mirror stainless steel sheets can be customized in terms of size, thickness, and finish to meet specific project requirements. Customization may involve cutting, shaping, or etching the surface for decorative purposes.

Q8:Are mirror stainless steel sheets suitable for outdoor applications?

A8:Yes, mirror stainless steel sheets are suitable for outdoor applications, but exposure to harsh environmental conditions may require periodic cleaning and maintenance to preserve the finish.

Q9:What are the limitations of mirror stainless steel sheets?

A9:Mirror stainless steel sheets may show fingerprints, smudges, or scratches more prominently compared to other finishes. Additionally, the initial cost may be higher than other materials, but the long-term durability and aesthetic appeal often justify the investment.

Q10:Where can I purchase mirror stainless steel sheets?

A10:Mirror stainless steel sheets are available from metal suppliers, manufacturers, and distributors specializing in stainless steel products. They may offer a range of sizes, grades, and finishes to suit different project needs.

These FAQs provide a comprehensive overview of mirror stainless steel sheets, their applications, benefits, maintenance, and customization options.

Post time: Jun-12-2024